Complete Monitoring Solutions

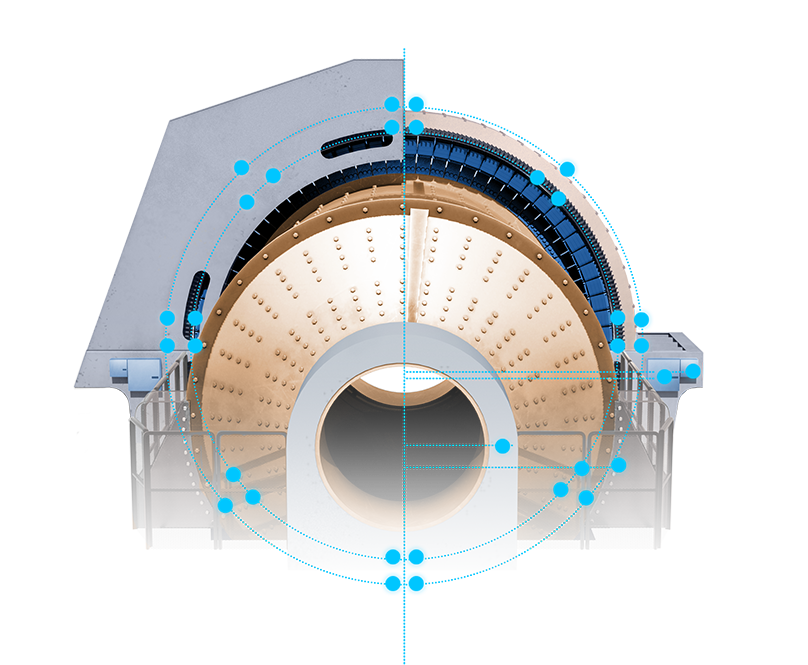

The online monitoring of a large Ball or a SAG Mill provides vital information on the health of the machine. More than just protection, VibroSystM provides ZOOM users with autonomous data analysis and first level diagnostics that are both predictive and preventative, which will significantly reduce machine downtime. Our complete monitoring solutions give our clients the necessary tools to actively improve machine efficiency and reliability.

Sensors

Precision & Reliability

In order to give our customers a precise prognosis on the condition of their machine, data accuracy is essential. VibroSystM sensors were all designed to withstand the harsh and robust variety of environments they are to be installed in, without compromising the accuracy needed to correctly monitor and protect your machine.

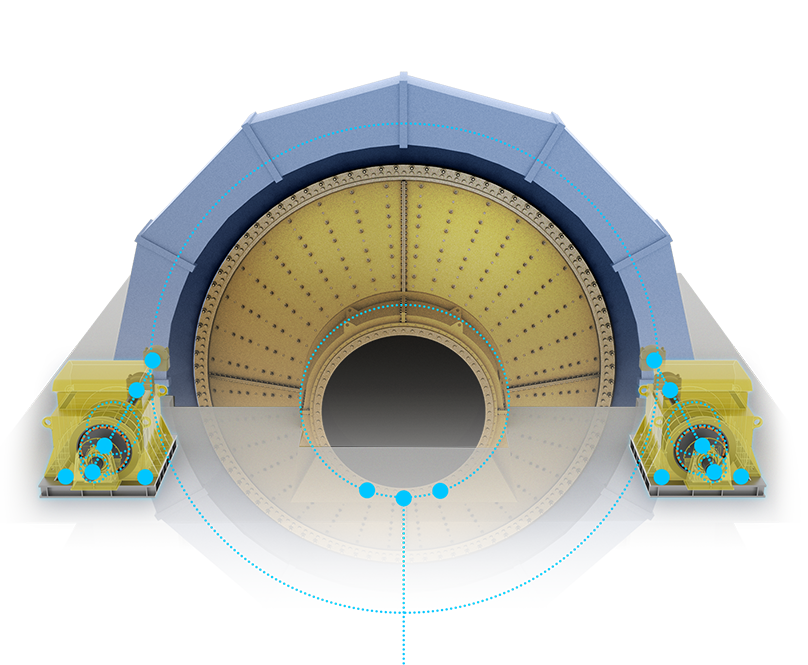

ZOOM Cabinet

& Acquisition Units

Protection, Monitoring & Analysis Unit

Combine all your quality control data acquisition units in one single space, and simultaneously monitor all the critical parameters on your machine.

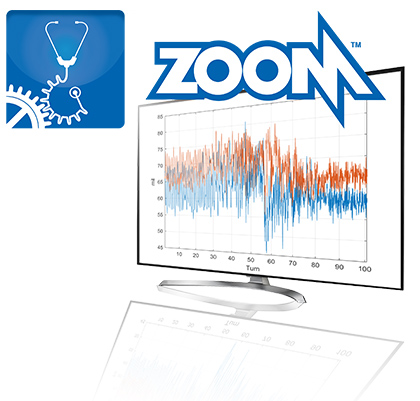

ZOOM Software

VibroSystM’s ZOOM software provides its users with a clear, real-time picture on the condition of their machine in any operating mode. The ZOOM software suite is the only one on the market that can be tailored to a user’s specific needs. It is composed of various acquisition services, which gives its users the possibility of choosing the parameters

to be monitored on their machines.

RIS

Results Interpretation Service

The specialists in our Tests & Diagnostics division provide clients with detailed reports on the general condition of their machines. They analyze and correlate all the information our systems collect and provide comprehensive training sessions on how to understand their machine behavior.

Generator Diagnostics

Asset Management Tool

- Mobile friendly, web-based diagnostic platform

- 24/7 on-demand support at your fingertips

- Analysis results displayed in easy to understand graphs

Complete Monitoring Solution

AIR GAP (ROTOR-STATOR)

MAGNETIC FLUX

VIBRATION & DISPLACEMENT

- FOA-100/200

- Stator bar absolute vibration (radial-tangential)

- End winding absolute vibration

- Phase leads absolute vibration

- Iso-phase bus absolute vibration

- PES-300 Serie

- Oil film clearance

- SBV-202

- Stator bar relative vibration (radial)

- VSM797S

- Stator Frame absolute vibration (radial)

- Stator Core absolute vibration (radial)

- Pressure plates absolute vibration (axial)

TEMPERATURE

- FOT

- End-winding

- Phase leads

- Iso-phase bus

- Knife switch

- TWR

- Rotor pole

- TWS

- Stator core

- Stator bar

- Pressure plates (end core)

ACQUISITION UNITS

ZOOM MONITORING CABINET

ZOOM SOFTWARE SUITE

RESULT INTERPRETATION SERVICE

TOP